-

-

Technical Support Contacts:

-

Phone: 262-746-3374

-

Email: techsupport@goffscw.com

-

Website: http://www.goffsenterprises.com

-

-

-

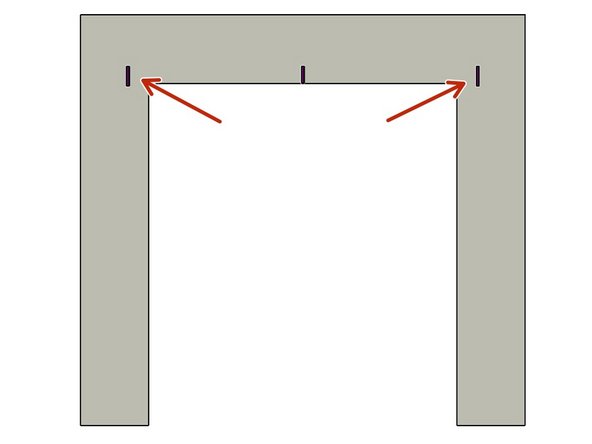

Measure the Opening Width near the top of the Opening.

-

Divide that overall width measurement in half to find the Centerline location.

-

Clearly Mark the Centerline location.

-

-

-

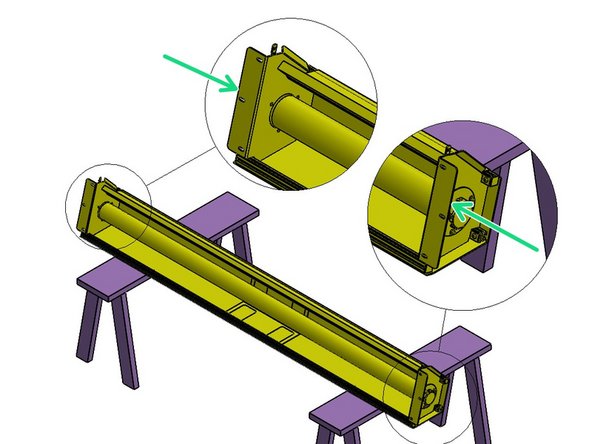

The Header Measuring Process is identical for all Door Models. The Door Model you are installing may be different from the Model shown.

-

Place the Door roll Header Assembly across a safe and level work surface, and rotate the roll assembly frame so that the Header Bracket Mounting flanges are facing upward.

-

Measure the total width of the whole roll assembly from outermost edge of one Header Bracket’s Mounting flange to the outermost edge of the opposite side.

-

Divide that number by 2. This number is 1/2 of the Header Width, and is used to determine the Header location on the Left and Right Sides of the opening.

-

-

-

Mark this dimension on each side of the Opening Center mark.

-

-

-

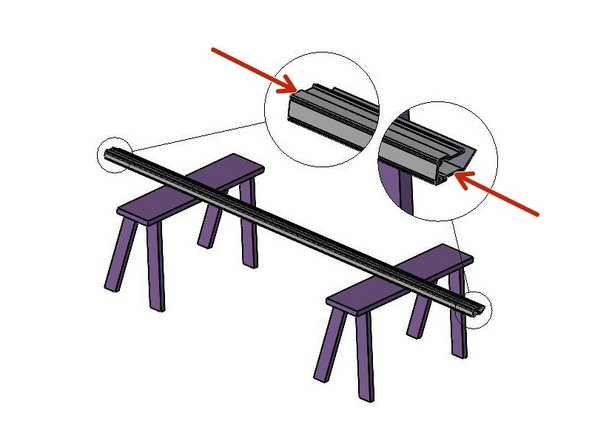

The Track Measuring Process is identical for all G1 Door Models. The Door Model you are installing may be different from the Model shown.

-

Set one of the Vertical Track Assemblies on your work surface.

-

Measure the Length of the Vinyl Track only.

-

ADD 3-1/4” to this number and take note.

-

This is the Height dimension needed to mark the location of the Bottom edge of the Header Mounting Brackets.

-

-

-

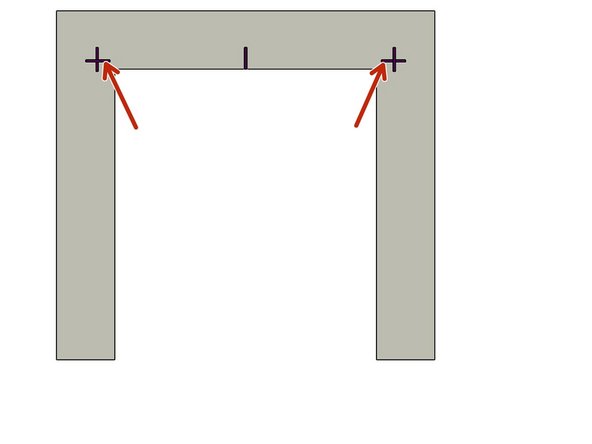

With the Calculated number (Track length + 3-1/4"), add a Horizontal line on each side of the Opening that intersects the previously drawn Vertical line.

-

-

-

Use two (2) people, and two ladders (at minimum).

-

Raise the Roll Header Assembly into place on the wall.

-

The bottom and outside edges of the Header Mounting Brackets should fit inside of Marks on the Mounting Surface.

-

Transfer the (3) Slot locations, per side, onto the Mounting Surface.

-

Prepare the locations for Hardware appropriate to the building material.

-

Loosely secure with three (3) sets of mounting hardware per side.

-

Level the Header Assembly, and fully tighten all six sets of hardware.

-

At this point leave the Door/Web Roll tied off and held in place as it comes.

-

-

-

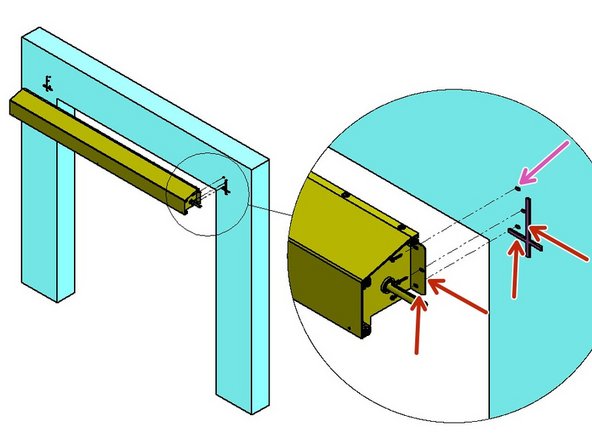

The Track Transition Bracket mounts to the Inside of the tab of the Header Assembly Mounting Bracket.

-

It is important to insert the Carriage Bolt from the inside of the Transition Bracket and the Washer and Hex Nut on the outside of the Header Bracket.

-

The Track must be plumb before securing it to the Mounting Surface.

-

-

-

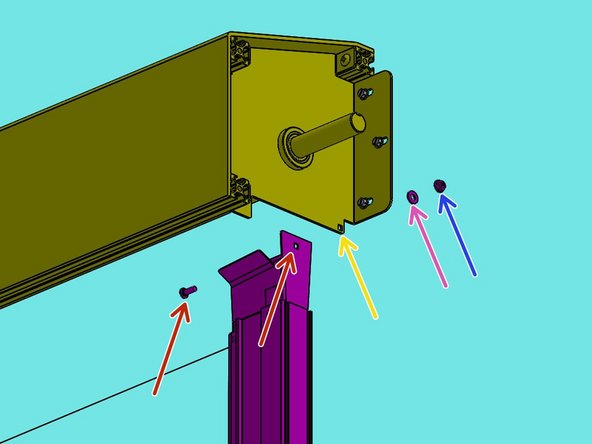

The Track assembly mounts to the Inside of the Header Assembly Mounting Bracket.

-

From the inside of the Track, Insert the Carriage Bolt fully through the Square hole.

-

Move the Track to the Inside of the Header Bracket, then push the Bolt through the Square hole in the Tab.

-

Slide the Washer onto the Bolt from the outside of the Header Bracket.

-

Then snug the Hex Nut on the Bolt.

-

-

-

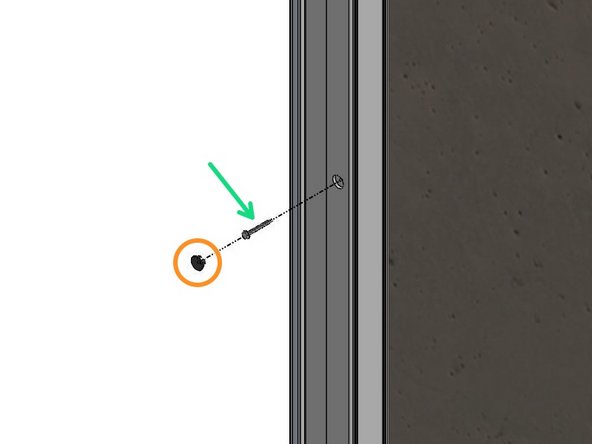

Remove the Black Plastic Plugs from the Track front. These are Mounting access Holes.

-

Use a Level to Plumb the Track and Transfer the Mounting Hole locations onto the Mounting Surface.

-

Remove the Track, and Prepare these locations for Hardware Appropriate to the Building Material.

-

Most Materials will Require Pre-Drilling Holes to Accept the Necessary Hardware.

-

With the Track Assembly Reinstalled and “Hanging” in this position, Plumb the Track to make sure it is Vertically Aligned.

-

Secure the Tracks to the Wall with Hardware Appropriate for your Mounting Surface Material.

-

Replace Plastic Caps.

-

-

-

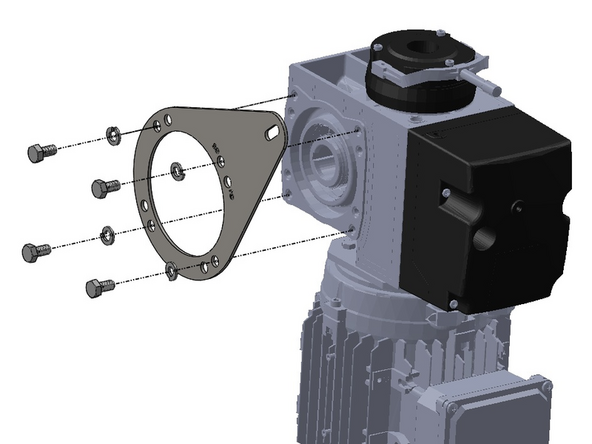

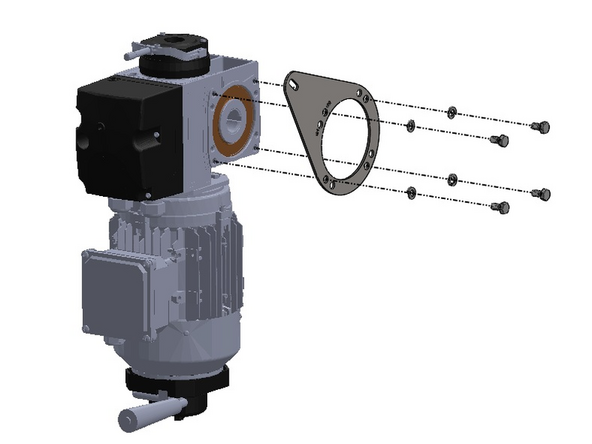

(4) M8-1.25 x 16mm Hex Bolts

-

(4) 5/16 Split-Lock Washers

-

(1) Motor Mount Anti-Torque Bracket

-

-

-

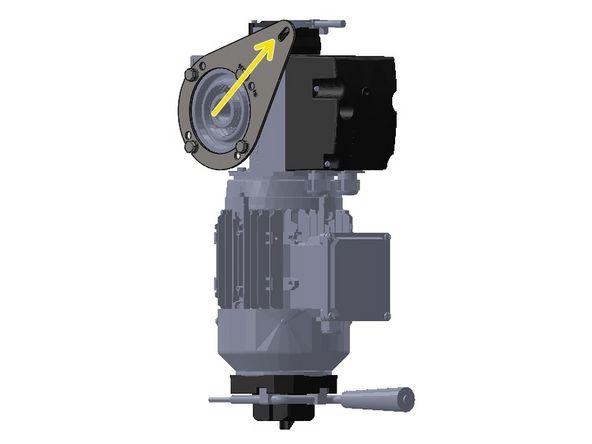

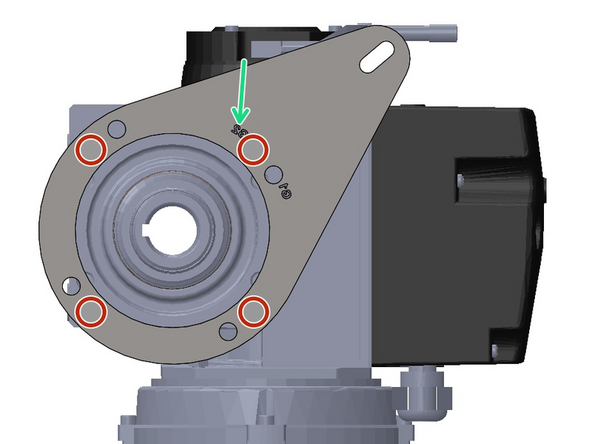

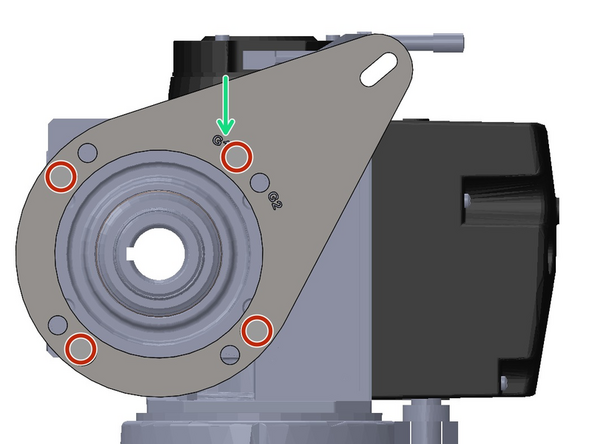

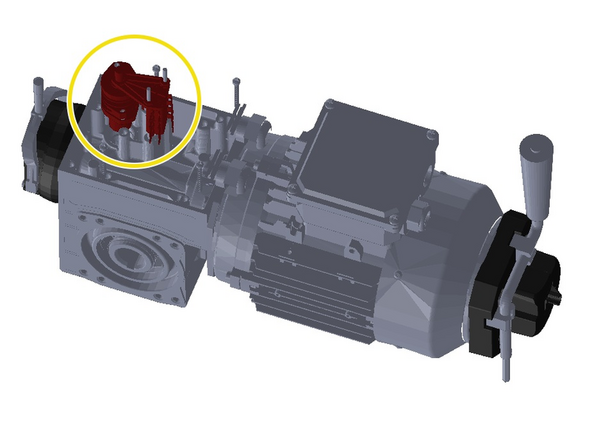

Note the Orientation of the Bracket in Relation to the Motor.

-

The Bracket has 2 Hole-Patterns Corresponding to G1 and G2 Doors. This ensures the proper Alignment when Installing the Motor Assembly onto a G1 or G2 Door.

-

For a G2 or Wash Guard Plus Door, Use the G2 Hole Pattern, and for a G1 or Model 2000 Door, use the G1 Hole Pattern.

-

On a LH Drive, G2 Door, the Letters will Read Normally/Forward when the Bracket is Mounted onto the Motor.

-

Place the Bracket up on the Motor with the proper Hole Alignment.

-

Place the Lock Washer onto the Screw and Fasten the Bracket onto the Motor.

-

-

-

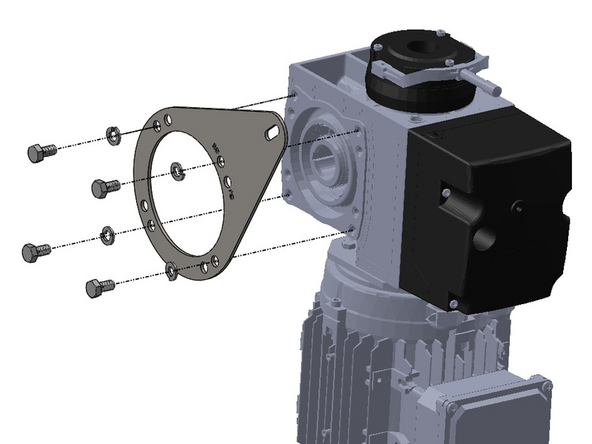

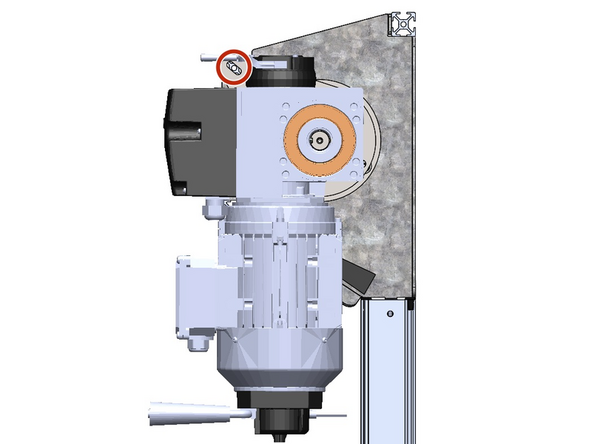

Note the Orientation of the Bracket in Relation to the Motor.

-

The Bracket has 2 Hole-Patterns Corresponding to G1 and G2 Doors. This ensures the proper Alignment when Installing the Motor Assembly onto a G1 or G2 Door.

-

For a G2 or Wash Guard Plus Door, Use the G2 Hole Pattern, and for a G1 or Model 2000 Door, use the G1 Hole Pattern.

-

On a RH Drive G2 Door, the Letters will Read Backwards when the Bracket is Mounted onto the Motor.

-

Place the Bracket up on the Motor with the proper Hole Alignment.

-

Place the Lock Washer onto the Screw and Fasten the Bracket onto the Motor.

-

-

-

Note the Orientation of the Bracket in Relation to the Motor.

-

The Bracket has 2 Hole-Patterns Corresponding to G1 and G2 Doors. This ensures the proper Alignment when Installing the Motor Assembly onto a G1 or G2 Door.

-

For a G2 or Wash Guard Plus Door, Use the G2 Hole Pattern, and for a G1 or Model 2000 Door, use the G1 Hole Pattern.

-

On a LH Drive G1 Door, the Letters will Read Backwards when the Bracket is Mounted onto the Motor.

-

Place the Bracket up on the Motor with the proper Hole Alignment.

-

Place the Lock Washer onto the Screw and Fasten the Bracket onto the Motor.

-

-

-

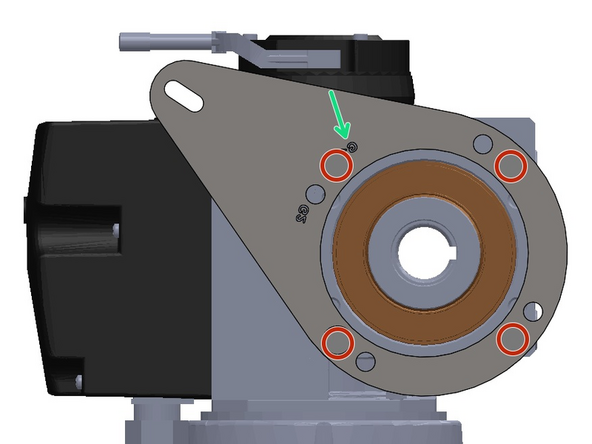

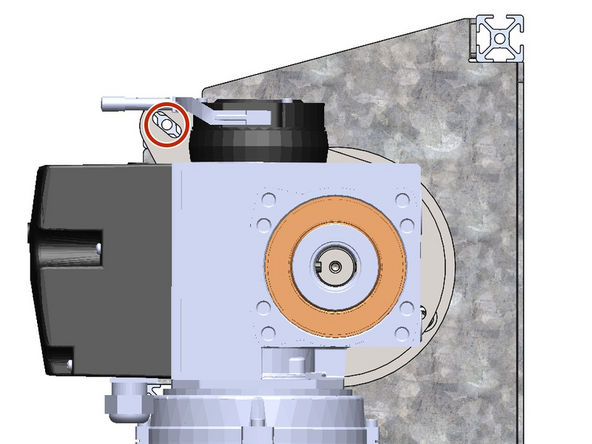

Note the Orientation of the Bracket in Relation to the Motor.

-

The Bracket has 2 Hole-Patterns Corresponding the G1 and G2 Doors. This ensures the proper Alignment when Installing the Motor Assembly onto a G1 or G2 Door.

-

For a G2 or Wash Guard Plus Door, Use the G2 Hole Pattern, and for a G1 or Model 2000 Door, use the G1 Hole Pattern.

-

On a RH Drive G1 Door, the Letters will Read Normally/Forward when the Bracket is Mounted onto the Motor.

-

Place the Bracket up on the Motor with the proper Hole Alignment.

-

Place the Lock Washer onto the Screw and Fasten the Bracket onto the Motor.

-

-

-

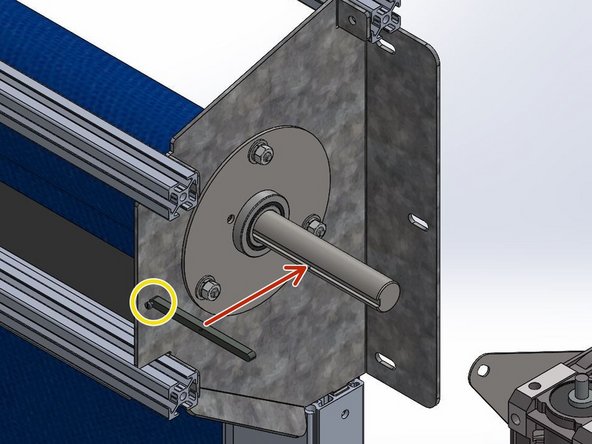

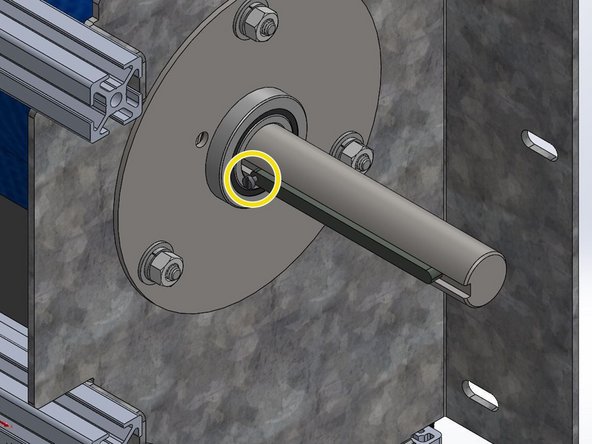

Install the Machine Key onto the Drive Shaft with the Set Screw Oriented Towards the Header (Between Motor and Door).

-

-

-

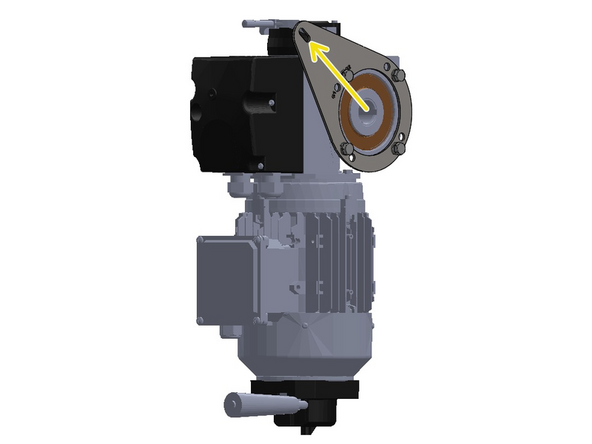

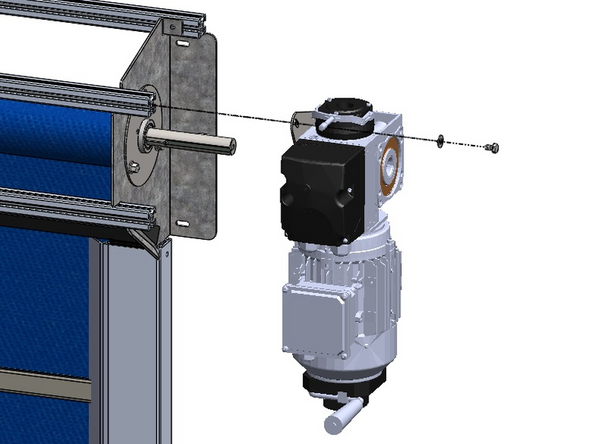

Slide the Motor onto the Shaft and Key.

-

Tilt the Motor to Align the Hole in the Motor Mount Bracket with the Hole on the end of the Upper, Front Rail.

-

This should result in the Motor being oriented Vertically and Plumb (See Image 2).

-

Place the 5/16 Flat Washer onto the 5/16-18 x 1/2in Hex Bolt and Fasten the Motor to the Door with a Ratchet or Impact Driver.

-

-

-

The Manaras direct-drive Motor comes Pre-Wired from the Factory.

-

In the field, you will need to Wire only the (2) Cables from the Motor into the Control Panel.

-

There is a Motor Cable, and a Limit Cable

-

This is a total of 12 Wires for Single-Phase.

-

And 13 Wires for 3-Phase.

-

-

-

Incoming Power is Terminated in the Lower-Left Corner of the Control Panel.

-

For Single-Phase Power, there will be 3 Wires:

-

Hot (L)

-

Neutral (N)

-

Ground (GND)

-

For 3-Phase Power, there will be 4 Wires:

-

Line 1 (L1), Line 2 (L2), Line 3 (L3), and Ground (GND)

-

-

-

Here is the Color-Coded Wiring Schema:

-

Black to M1

-

White to M2

-

Blue to M3

-

Red to M4

-

Green to Ground Screw

-

-

-

Blue to B1

-

Blue w/ Black Stripe to B2

-

Orange w/ Black Stripe to 1

-

Orange to 2

-

Red to 3

-

Red w/ Black Stripe to 4

-

Black to 5

-

Brown to 6

-

-

-

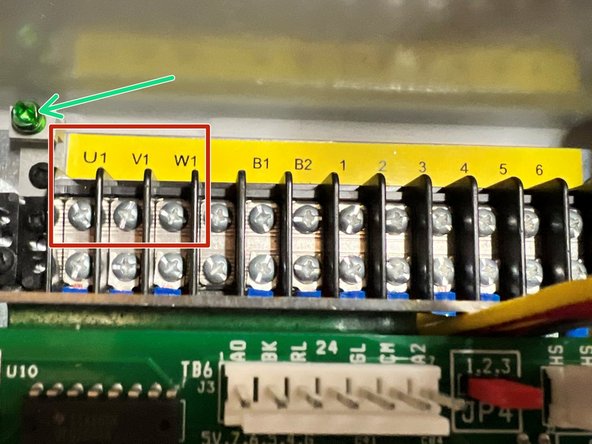

Here is the Color-Coded Wiring Schema:

-

White to U1

-

Red to V1

-

Black to W1

-

Green to Ground Screw

-

-

-

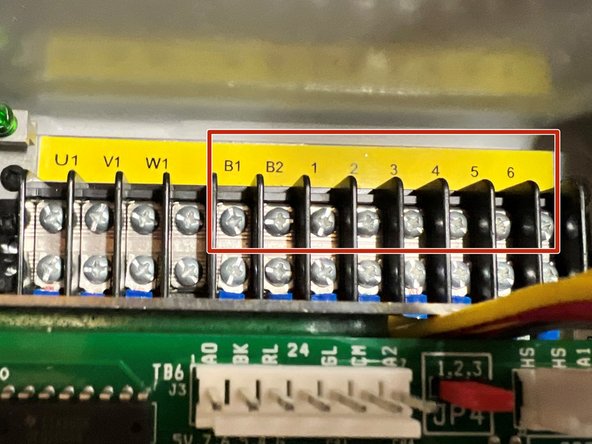

Blue to B1

-

Blue w/ Black Stripe to B2

-

Orange w/ Black Stripe to 1

-

Orange to 2

-

Red to 3

-

Red w/ Black Stripe to 4

-

Black to 5

-

Brown to 6

-

-

-

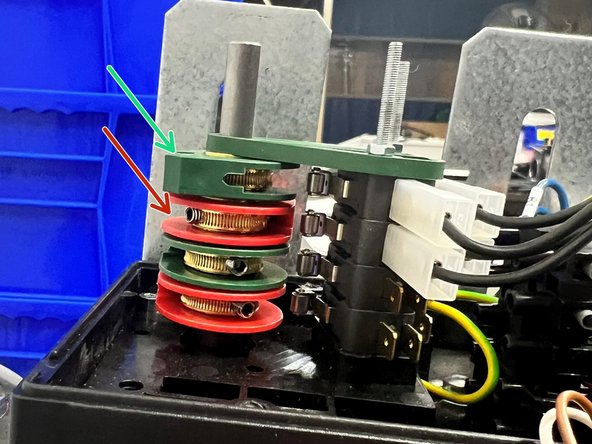

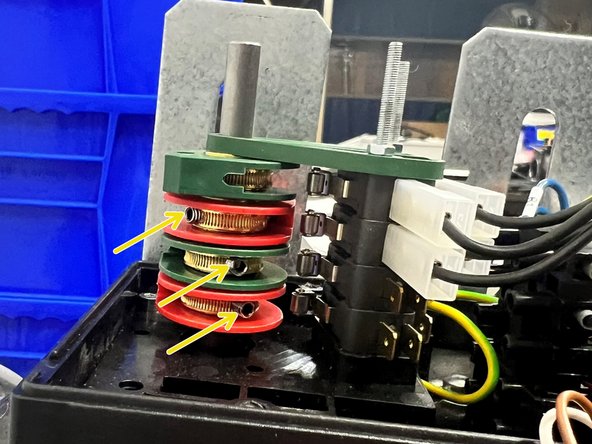

Remove the Black Cover from the Motor to expose the Mechanical-Limit Assembly.

-

Underneath, there is (2) Green Limit Cams, and (2) Red Limit Cams in Alternating Order.

-

The Top, Green Limit Cam (closest to you) is for the Open-Limit.

-

The Red Limit Cam (just below the Green one) is for the Close-Limit.

-

The (2) remaining Cams are Auxiliary, and could be used for Interlocking, or if you experience a failure in one or both of the Top (2) Limit Cams/Switches.

-

-

-

The top, Green (Open) Limit Cam will Rotate Clockwise until it hits the Limit Switch.

-

The Red (Close) Limit Cam will Rotate Counter-Clockwise until it hits the Limit Switch.

-

The Limit Cams can be loosened and Adjusted with the Built-in Set Screws.

-

-

-

Run the Door to the desired Closed Position.

-

Loosen the Red Cam's Set Screw, and Rotate the Cam Counter-Clockwise until the Lobe hits the Limit Switch. You will hear an Audible Click.

-

Hold the Cam in this Position, and Tighten the Set Screw to hold it there.

-

Run the Door to the desired Open Position.

-

Loosen the Green Cam's Set Screw, and Rotate the Cam Clockwise until the Lobe hits the Limit Switch. You will hear an Audible Click.

-

Hold the Cam in this Position, and Tighten the Set Screw to hold it there.

-

Test the Limits to confirm accuracy and repeatability. Make any adjustments as necessary.

-

Almost done!

Finish Line