-

-

Technical Support Contacts:

-

Phone: 262-746-3374

-

Email: techsupport@goffscw.com

-

Website: http://www.goffsenterprises.com

-

-

-

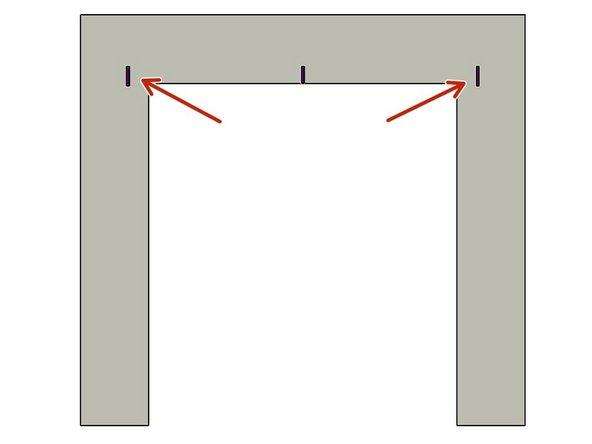

Measure the Opening Width near the top of the Opening.

-

Divide that overall width measurement in half to find the Centerline location.

-

Clearly Mark the Centerline location.

-

-

-

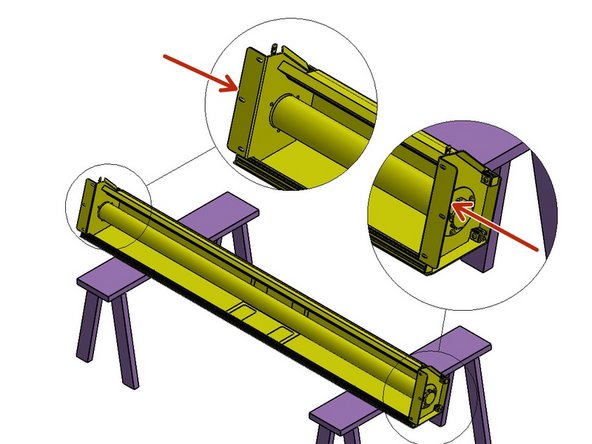

The Header Measuring Process is identical for all Door Models. The Door Model you are installing may be different from the Model shown.

-

Place the Door roll Header Assembly across a safe and level work surface, and rotate the roll assembly frame so that the Header Bracket Mounting flanges are facing upward.

-

Measure the total width of the whole roll assembly from outermost edge of one Header Bracket’s Mounting flange to the outermost edge of the opposite side.

-

Divide that number by 2. This number is 1/2 of the Header Width, and is used to determine the Header location on the Left and Right Sides of the opening.

-

-

-

Mark this dimension on each side of the Opening Center mark.

-

-

-

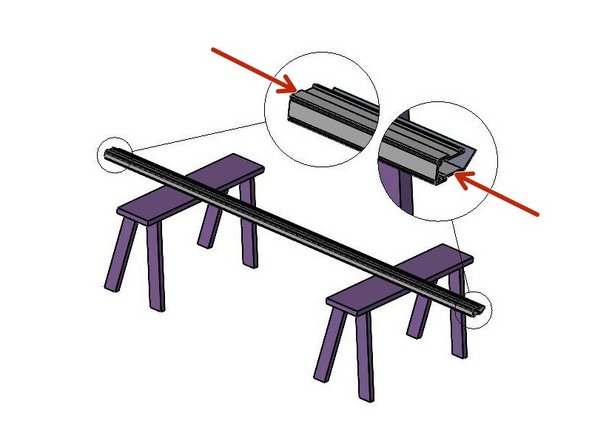

The Track Measuring Process is identical for all G1 Door Models. The Door Model you are installing may be different from the Model shown.

-

Set one of the Vertical Track Assemblies on your work surface.

-

Measure the Length of the Vinyl Track only.

-

ADD 3-1/4” to this number and take note.

-

This is the Height dimension needed to mark the location of the Bottom edge of the Header Mounting Brackets.

-

-

-

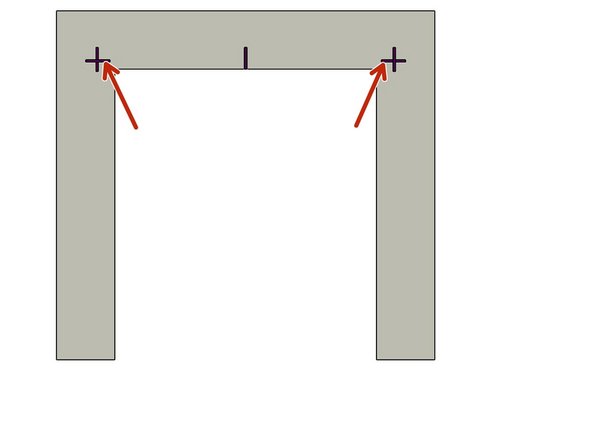

With the Calculated number (Track length + 3-1/4"), add a Horizontal line on each side of the Opening that intersects the previously drawn Vertical line.

-

-

-

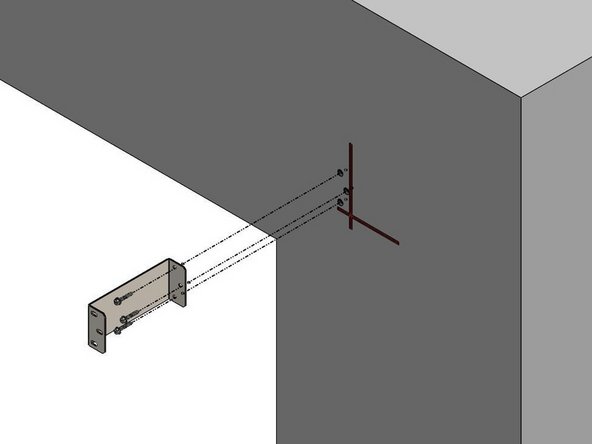

Orient the slotted end of the Header Mounting Projection Bracket against the Mounting Surface.

-

Orient the flange outward.

-

Align the Bottom surface of the Header Mounting Bracket with the Horizontal line on the Mounting Surface.

-

Align the Outer edge of the Header Mounting Bracket with the Vertical line on the Mounting Surface.

-

Trace the slotted mounting slots onto the Mounting Surface.

-

-

-

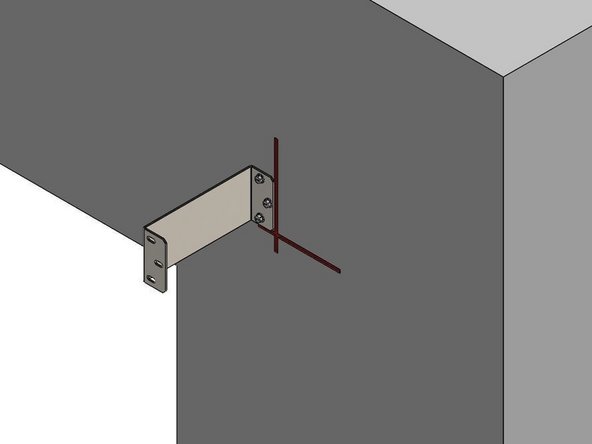

Loosely fasten Bracket to the Mounting Surface with appropriate hardware.

-

Plumb the Bracket.

-

Tighten Hardware securely.

-

Repeat for the other Header Mounting Bracket.

-

-

-

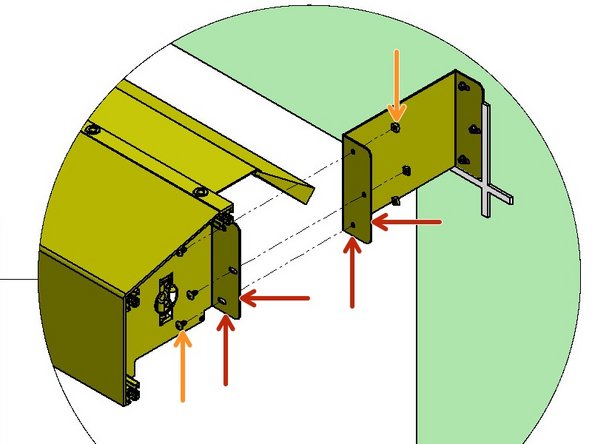

Use two (2) people, and two ladders at minimum to Install the Roll Header Assembly.

-

Raise the Roll Header Assembly into place on the Projection Brackets.

-

Loosely tighten with three (3) sets of ¼-20 screws and hex nuts per side.

-

Do not fully tighten hardware until the Header Assembly Brackets are aligned with the Projection Bracket’s edges.

-

Check the Header Assembly for level, and make any necessary final adjustments.

-

Once aligned, fully tighten all six sets of hardware.

-

At this point leave the roll assembly tied off and held in place as it comes.

-

-

-

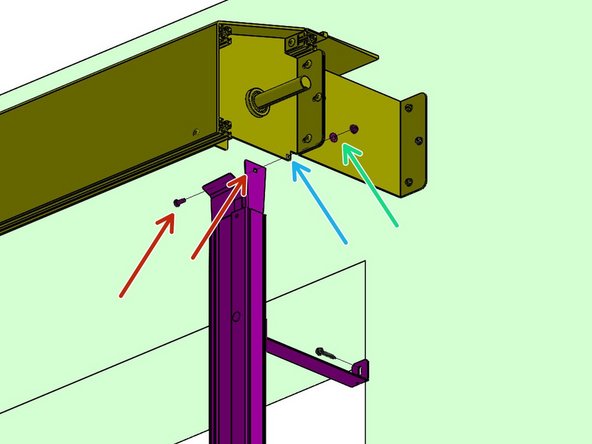

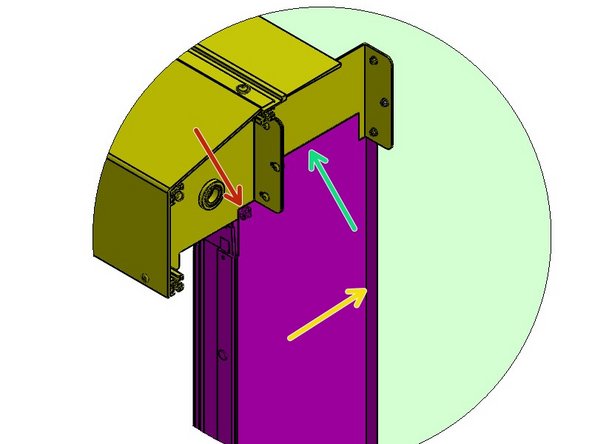

The Track Transition Bracket mounts to the Inside of the tab of the Header Assembly Mounting Bracket.

-

It is important to insert the Carriage Bolt from the inside of the Transition Bracket and the Washer and Hex Nut on the outside of the Header Bracket.

-

The Track must be plumb before securing it to the Mounting Surface.

-

-

-

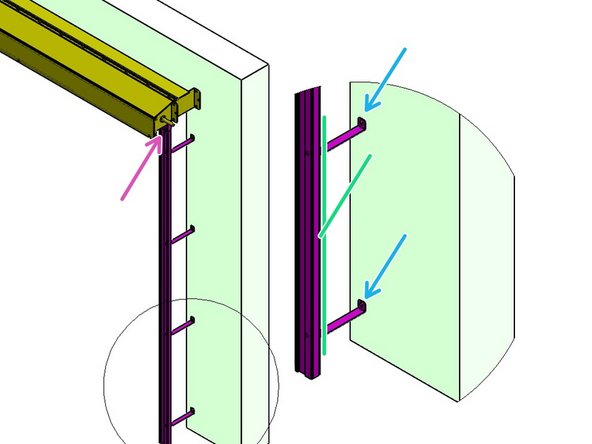

Tracks are marked for orientation as Left Side, and Right Side.

-

Lay the two Vertical Track Assemblies on your work surface.

-

Un-roll the Side Seal material.

-

Remove the Plugs from the front of the Track

-

Locate the Track Projection Mount Brackets, four (4) per Track.

-

Locate four the ¼-20 Screws and Flanged Nuts.

-

-

-

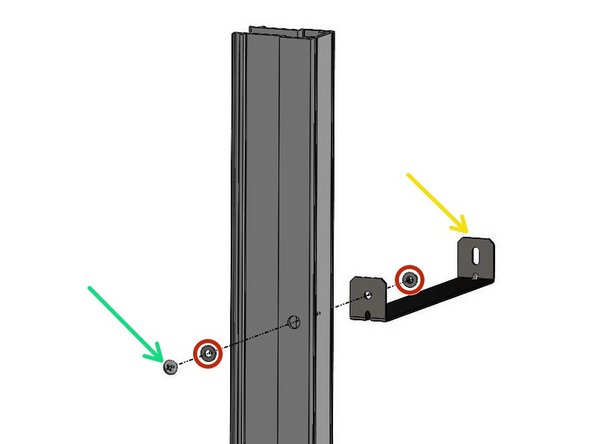

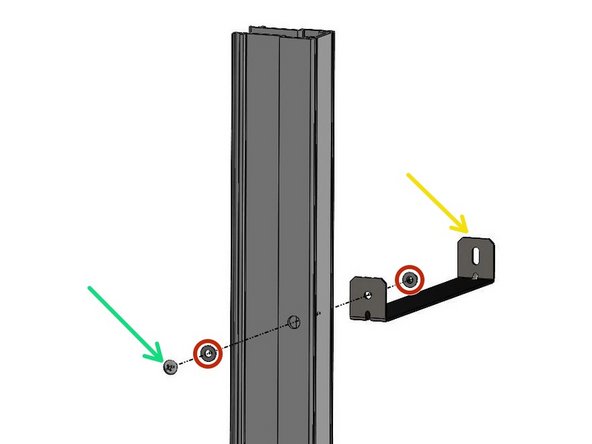

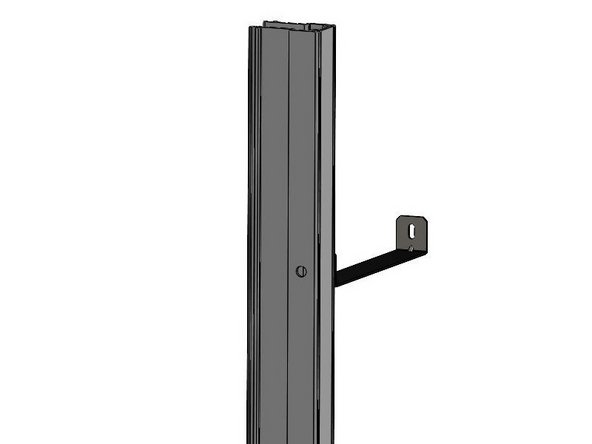

Push a screw through the hole in the back surface from the inside of the Track.

-

Slip the Projection Bracket onto the 1/4-20 Screw, with the hole facing the Track, and then thread the nut, onto the screw.

-

The slotted end of the Projection Bracket will fasten to the Mounting Surface in a later step.

-

These Brackets should be Mounted so that their Flanges point Vertically (as shown).

-

Fully tighten the hardware for these brackets once they are aligned with the Track edges.

-

Re-install the Plug Caps into the hardware access holes on the front side of the Tracks.

-

-

-

The Track assembly mounts to the Inside of the Header Assembly Mounting Bracket.

-

From the inside of the Track, Insert the Carriage Bolt fully through the Square hole.

-

Then push the Carriage Bolt through the Header Bracket from the Inside.

-

Slide the Washer onto the Bolt from the outside of the Header Bracket , and snug the Hex Nut on the Bolt. (This Track Mount hardware will be removed in later steps.)

-

-

-

Plumb the Track Left to Right.

-

Transfer the Mounting Hole locations onto the Mounting Surface.

-

Remove the Track, and prepare these locations for Hardware appropriate to the Building Material.

-

Reinstall, snugly, the Track Mount Hardware. (It will be removed again in a later step.)

-

With the Track “hanging” in this position, Plumb the Track Left to Right.

-

Secure the Track Brackets to the Mounting Surface.

-

Tighten all of the Hardware Securely.

-

-

-

Remove the Track Mounting Hardware.

-

Re-Install the Hardware with the Side Seal Grommet under the Washer and Nut, then tighten Securely.

-

Affix the Hook and loop Material to the Header Bracket along the Top Edge of the Side Seal Material.

-

Fold and Secure the Side Seal Material to the Mounting Surface.

-

Almost done!

Finish Line