-

-

Technical Support Contacts:

-

Phone: 262-746-3374

-

Email: techsupport@goffscw.com

-

Website: http://www.goffsenterprises.com

-

-

-

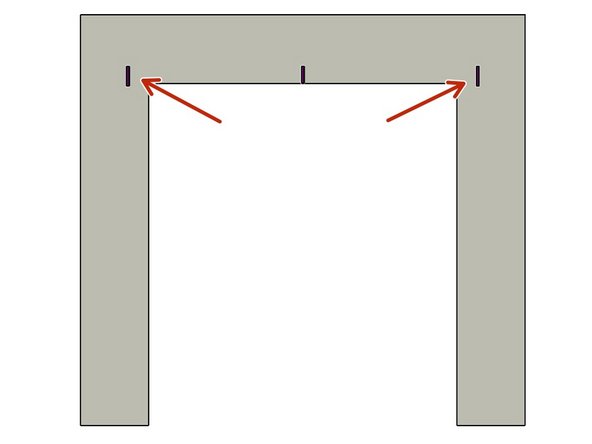

Measure the Opening Width near the top of the Opening.

-

Divide that overall width measurement in half to find the Centerline location.

-

Clearly Mark the Centerline location.

-

-

-

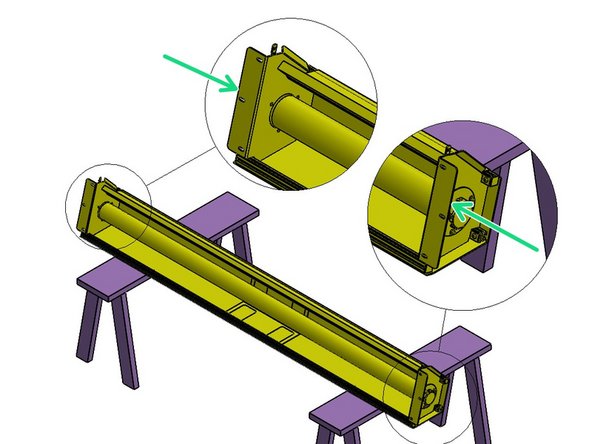

The Header Measuring Process is identical for all Door Models. The Door Model you are installing may be different from the Model shown.

-

Place the Door roll Header Assembly across a safe and level work surface, and rotate the roll assembly frame so that the Header Bracket Mounting flanges are facing upward.

-

Measure the total width of the whole roll assembly from outermost edge of one Header Bracket’s Mounting flange to the outermost edge of the opposite side.

-

Divide that number by 2. This number is 1/2 of the Header Width, and is used to determine the Header location on the Left and Right Sides of the opening.

-

-

-

Mark this dimension on each side of the Opening Center mark.

-

-

-

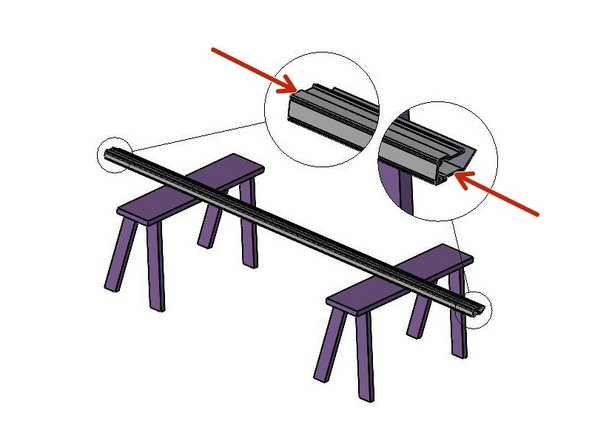

The Track Measuring Process is identical for all G1 Door Models. The Door Model you are installing may be different from the Model shown.

-

Set one of the Vertical Track Assemblies on your work surface.

-

Measure the Length of the Vinyl Track only.

-

ADD 3-1/4” to this number and take note.

-

This is the Height dimension needed to mark the location of the Bottom edge of the Header Mounting Brackets.

-

-

-

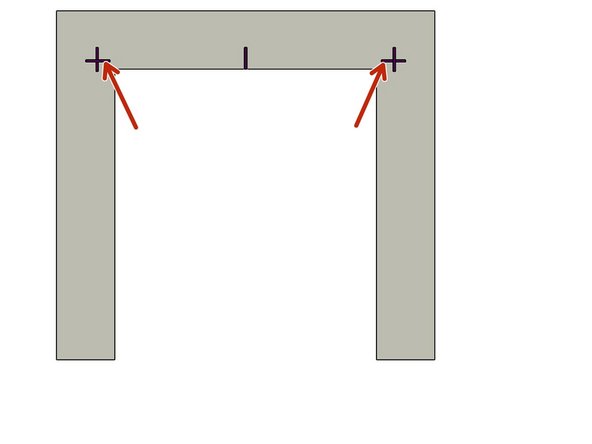

With the Calculated number (Track length + 3-1/4"), add a Horizontal line on each side of the Opening that intersects the previously drawn Vertical line.

-

-

-

Use two (2) people, and two ladders (at minimum).

-

Raise the Roll Header Assembly into place on the wall.

-

The bottom and outside edges of the Header Mounting Brackets should fit inside of Marks on the Mounting Surface.

-

Transfer the (3) Slot locations, per side, onto the Mounting Surface.

-

Prepare the locations for Hardware appropriate to the building material.

-

Loosely secure with three (3) sets of mounting hardware per side.

-

Level the Header Assembly, and fully tighten all six sets of hardware.

-

At this point leave the Door/Web Roll tied off and held in place as it comes.

-

-

-

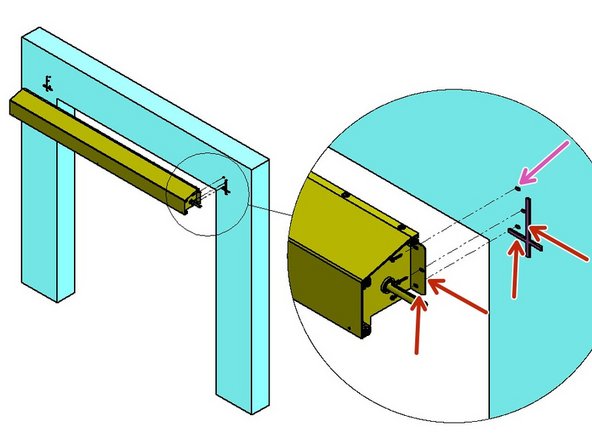

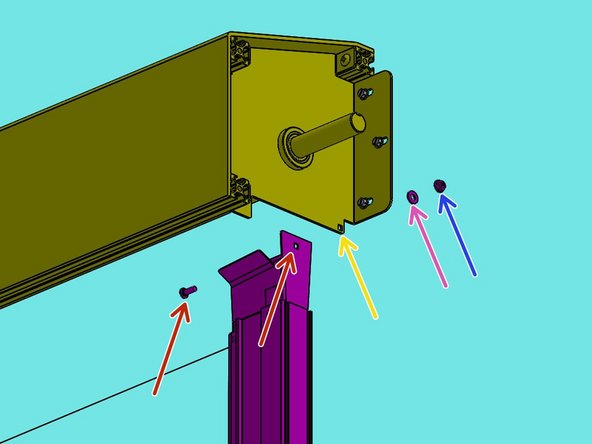

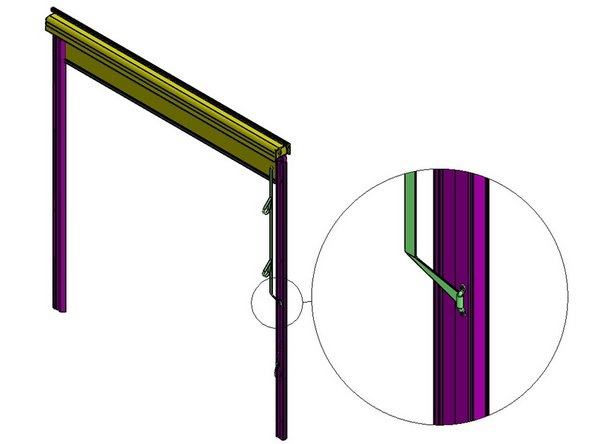

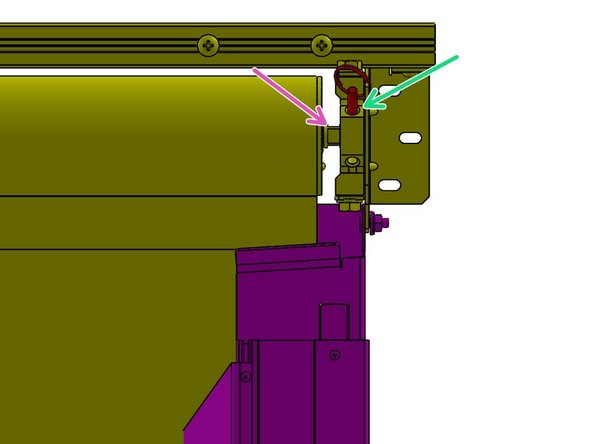

The Track Transition Bracket mounts to the Inside of the tab of the Header Assembly Mounting Bracket.

-

It is important to insert the Carriage Bolt from the inside of the Transition Bracket and the Washer and Hex Nut on the outside of the Header Bracket.

-

The Track must be plumb before securing it to the Mounting Surface.

-

-

-

The Track assembly mounts to the Inside of the Header Assembly Mounting Bracket.

-

From the inside of the Track, Insert the Carriage Bolt fully through the Square hole.

-

Move the Track to the Inside of the Header Bracket, then push the Bolt through the Square hole in the Tab.

-

Slide the Washer onto the Bolt from the outside of the Header Bracket.

-

Then snug the Hex Nut on the Bolt.

-

-

-

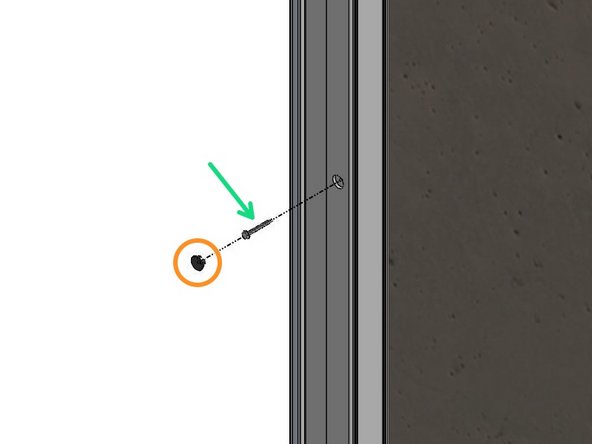

Remove the Black Plastic Plugs from the Track front. These are Mounting access Holes.

-

Use a Level to Plumb the Track and Transfer the Mounting Hole locations onto the Mounting Surface.

-

Remove the Track, and Prepare these locations for Hardware Appropriate to the Building Material.

-

Most Materials will Require Pre-Drilling Holes to Accept the Necessary Hardware.

-

With the Track Assembly Reinstalled and “Hanging” in this position, Plumb the Track to make sure it is Vertically Aligned.

-

Secure the Tracks to the Wall with Hardware Appropriate for your Mounting Surface Material.

-

Replace Plastic Caps.

-

-

-

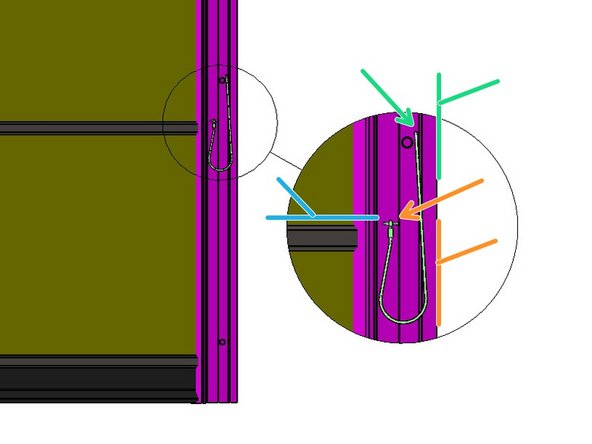

The top edge of the second lowest Wind Bar of the Door will be where the Lock Pin meets and holds the Door in the closed position. A factory-cut notch is located in the Door Panel, on the right-hand side, to allow the Lock Pin to pass through the Door.

-

Using the Pull Strap, pull the Door down/closed until a satisfactory seal with the floor is achieved.

-

Mark the location of the top edge of the second lowest Wind Bar onto the Right-Hand Door Track.

-

Release the Pull Strap to allow the door to return to the Open Position.

-

Drill a ¼” Dia. hole through both legs of the track 2” from the right (outside of the track) which intersects your line.

-

Drill a 3/16” hole, a few inches above the ¼” hole, at about ¾” from the right (outside of the Track).

-

Insert the Lanyard/cord through this hole, and tie a knot on that end.

-

To hold the Door in the Closed position: Pull the Door down to the closed position, and insert the Lock-Pin above the Wind Bar through the front and rear holes of the Door Track.

-

-

-

With the Door in the Open Position:

-

Pull the loose end of the long Strap through the Tie-off Bracket attached to the Right-Side Door Track.

-

Use the Buckle provided to secure the long Pull Strap to the loose end

-

Adjust the length to set the upper Stop Point of the Door.

-

-

-

Raise the Door to the fully Open position. This Unloads much, but NOT all, of the Spring Loading.

-

To fully Unload the Spring, with the Door raised, pull the Pin. The Shaft may spin inside as the Spring fully unloads.

-

Secure the Door Webbing to the Roll Tube to hold it in place during this process.

-

-

-

Spring tension is maintained either with a ½” open-end wrench on the wrench flats, or with the Quick-Release pin.

-

Spring tension is increased/decreased with a two-step process.

-

To increase spring tension, insert the open-end wrench onto the wrench flats and hold firmly

-

then pull the Quick-Release pin.

-

Pull the wrench down (CCW) until the pin can be replaced – about a quarter turn.

-

Repeat this two-step process about 8 times equaling about 2 full turns on the spring.

-

Release the ties on the Door Roll Assembly.

-

-

-

Pull the Door fully Closed, then release the Strap.

-

Note the Opening Stop Point.

-

Adjust the Opening Stop Point by increasing/decreasing the tension 1 quarter turn.

-

Test and adjust as needed.

-

Almost done!

Finish Line