-

-

Technical Support Contacts:

-

Phone: 262-746-3374

-

Email: techsupport@goffscw.com

-

Website: http://www.goffsenterprises.com

-

-

-

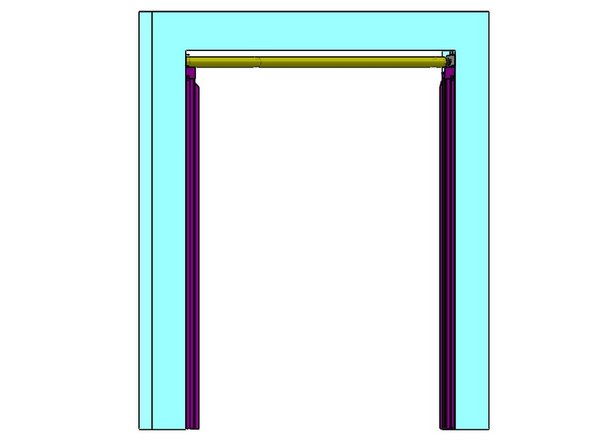

The Door Header must be level for the Door to operate properly.

-

Check the door opening Header for level, and adjust the installation accordingly.

-

Locate the Left Hand Header Mounting Bracket, and prepare to work on the upper Left of the Door Opening.

-

Align the top edge of the Bracket to the upper surface of the Door Opening.

-

Align the back edge of the Bracket to the Back Edge of the Door Opening.

-

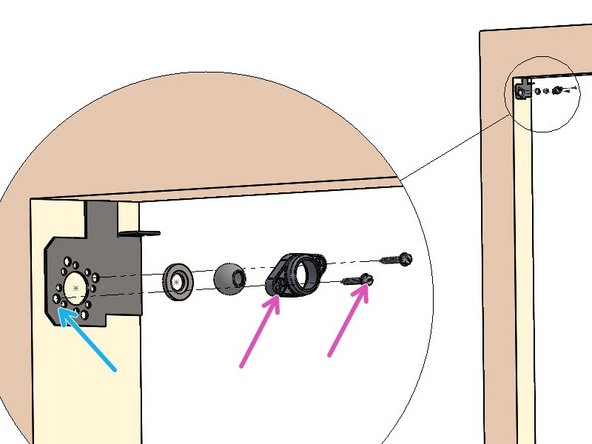

Measure the Hole Centers on the Bearing Block to help determine which Mounting Holes will be used in the Bracket.

-

Transfer two hole locations onto the Mounting Surface.

-

-

-

Prepare the Mounting Surface for Wall Mounting Hardware.

-

Insert your Wall Mounting Hardware through Idler Bearing assembly (3 pieces).

-

Then through the Left Hand Header Mounting Bracket, into the Mounting Surface.

-

-

-

The Door Header must be level for the Door to operate properly.

-

Locate the Right Hand Header Mounting Bracket, and prepare to work on the upper Right of the Door Opening.

-

Align the top edge of the Bracket to the upper surface of the Door Opening.

-

Align the back edge of the Bracket to the Back Edge of the Door Opening.

-

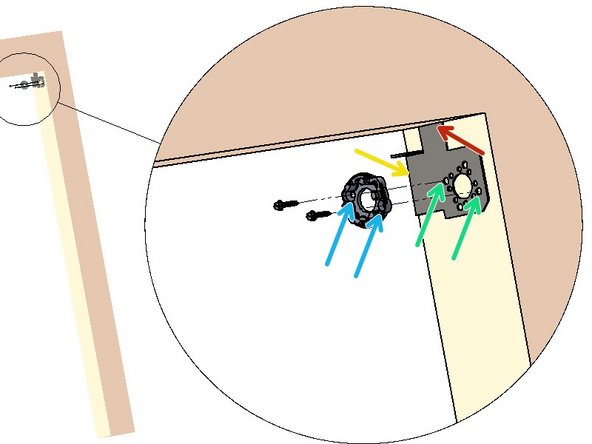

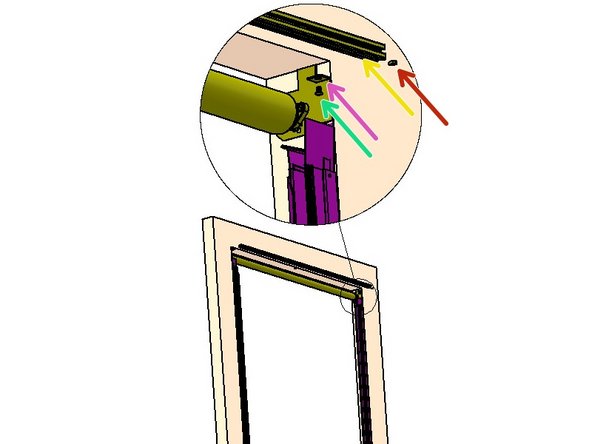

Measure the Hole Centers on the Motor Mounting Block to help determine which Mounting Holes will be used in the Bracket.

-

Transfer two hole locations onto the Mounting Surface.

-

-

-

Prepare the Mounting Surface for Mounting Hardware.

-

Insert your Wall Mounting Hardware through Motor Mounting Cap.

-

Then through the Right Hand Header Mounting Bracket, into the Mounting Surface.

-

-

-

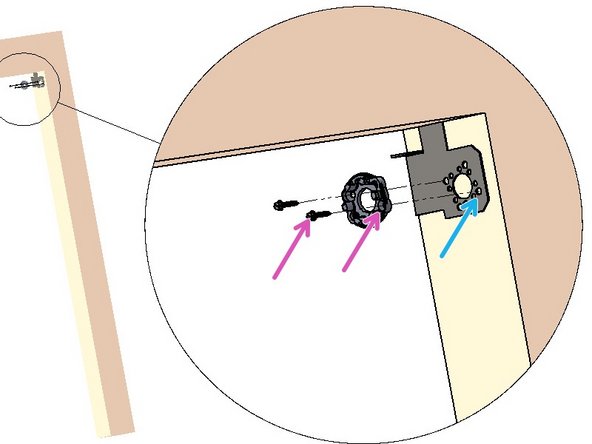

Locate the Left Hand Track (Marked LH).

-

Align the mating surfaces of the Track Transition Bracket -

-

-to the Header Mounting Bracket.

-

Plumb Track Assembly (Front to Back).

-

Use a 2nd Person to hold the Track in place.

-

Transfer the Mounting Hole locations onto the Mounting Surface.

-

-

-

Prepare the Hole locations for the Mounting Hardware.

-

Check for Plumb before securing the Track tightly to the Mounting Surface.

-

Repeat process for the other Track assembly.

-

-

-

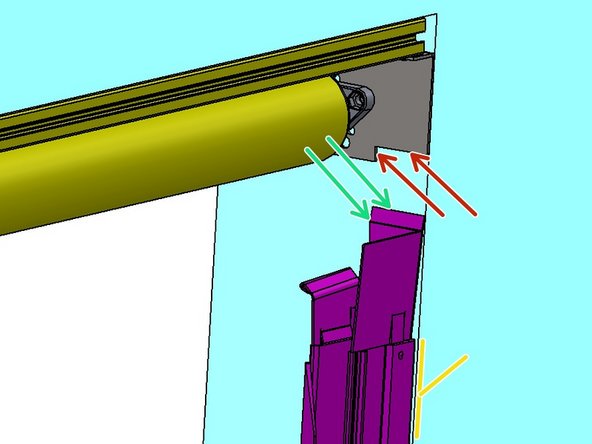

Use 2 people, and 2 ladders at minimum.

-

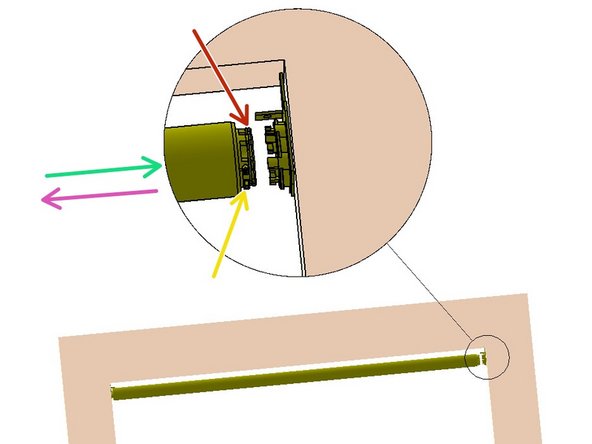

Verify that (or Install) the "C" Clip is installed on the Motor.

-

Raise the Header Assembly, and insert the Idler Shaft into the installed Idler Bearing Assembly at Upper Left.

-

Rotate the Roll Header so the the Switches (Yellow and White) are facing Down/Front (for easy access later).

-

At the Right Side, push the Header Assembly toward the Idler side to compress the (spring loaded) Idler Shaft.

-

Align the Motor with the Bracket, then pull the Header Assembly toward the wall until the “C” Clip snaps into place around the Motor Mounting Bracket's Hooks.

-

At this point leave the Roll Assembly tied off and held in place as it comes.

-

-

-

The Valance Assembly Mounts on top of the bent Flanges of the installed Header Mounting Brackets.

-

The Valance Beam has pre-installed Mounting Hardware.

-

Remove two Screws from the Valance Beam.

-

Leave the Nuts in the groove near the ends.

-

Lift the Beam into place on top of the Flanges.

-

With a Screwdriver, move the Nuts into place above the Mounting Flange holes.

-

Re-install the Screws through the hole in each Mounting Flange, then secure them in the captured Nuts.

-

Almost done!

Finish Line